-

tel:

+86 17625110110 -

email:

klaus@hralloys.com

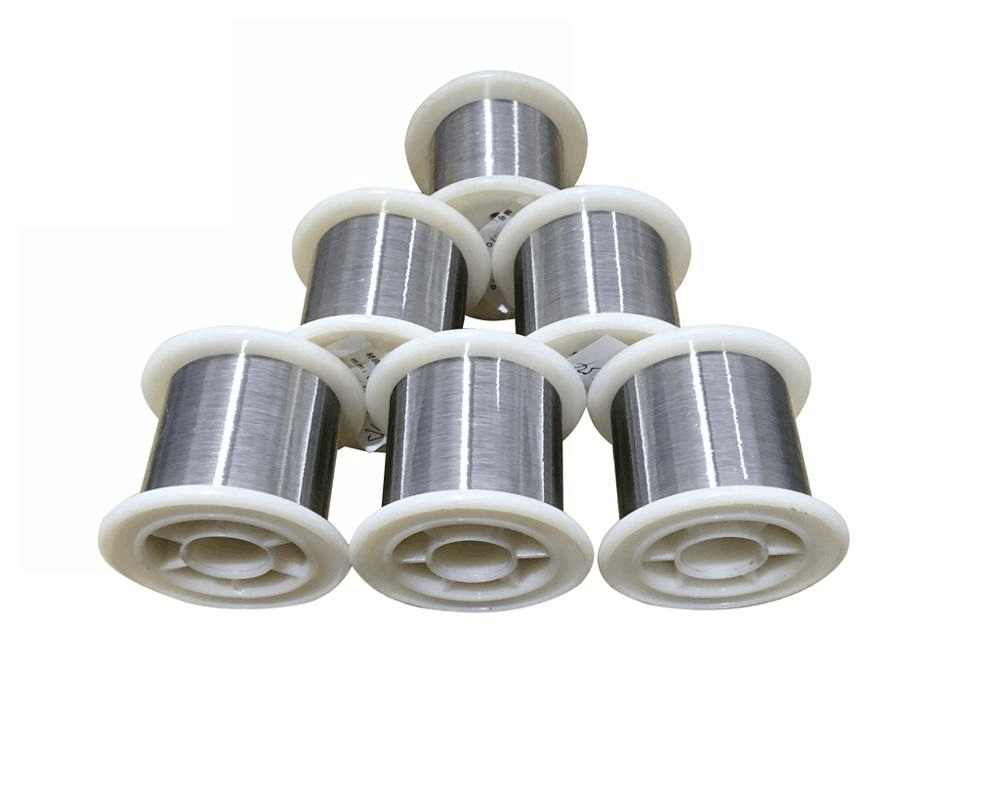

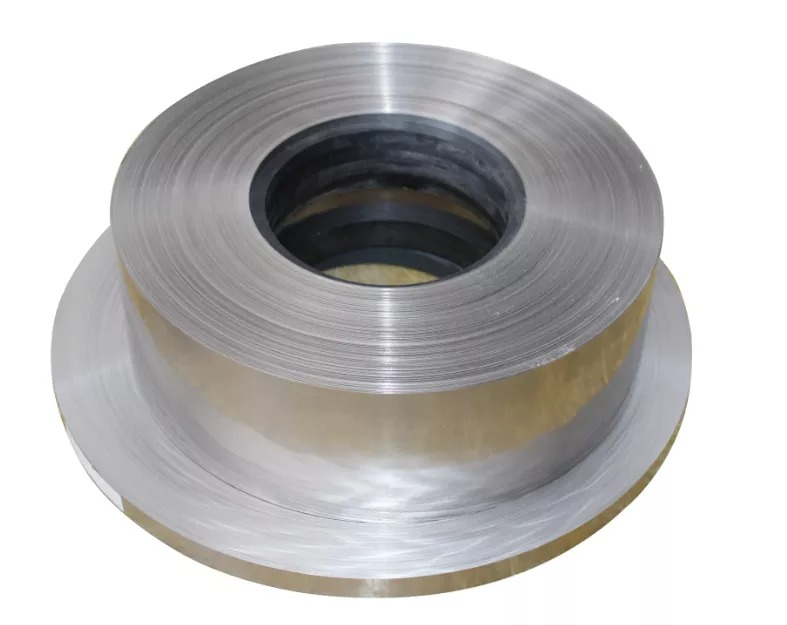

Promotional price for Cobalt-based Elastic Alloy 3J21 Wire, Elgiloy Strip for Sale

Chemical Composition (%):

Chemcial Composition(%) | ||||

C | Mn | Si | P | S |

0.07-0.12 | 1.7-2.3 | ≤0.60 | ≤0.015 | ≤0.015 |

Ni | Cr | Co | Mo | Fe |

14.0-16.0 | 19.0-21.0 | 39.0-41.0 | 6.5-7.5 | Bal. |

Mechanical Property of Elgiloy alloy | |||||

Shape | Delivery State | Thickness&Diameter/mm | Property&Classfication | Mechanical Property | |

Tensile Strength (ób/Mpa) | Elongation δ(%) | ||||

≥ | |||||

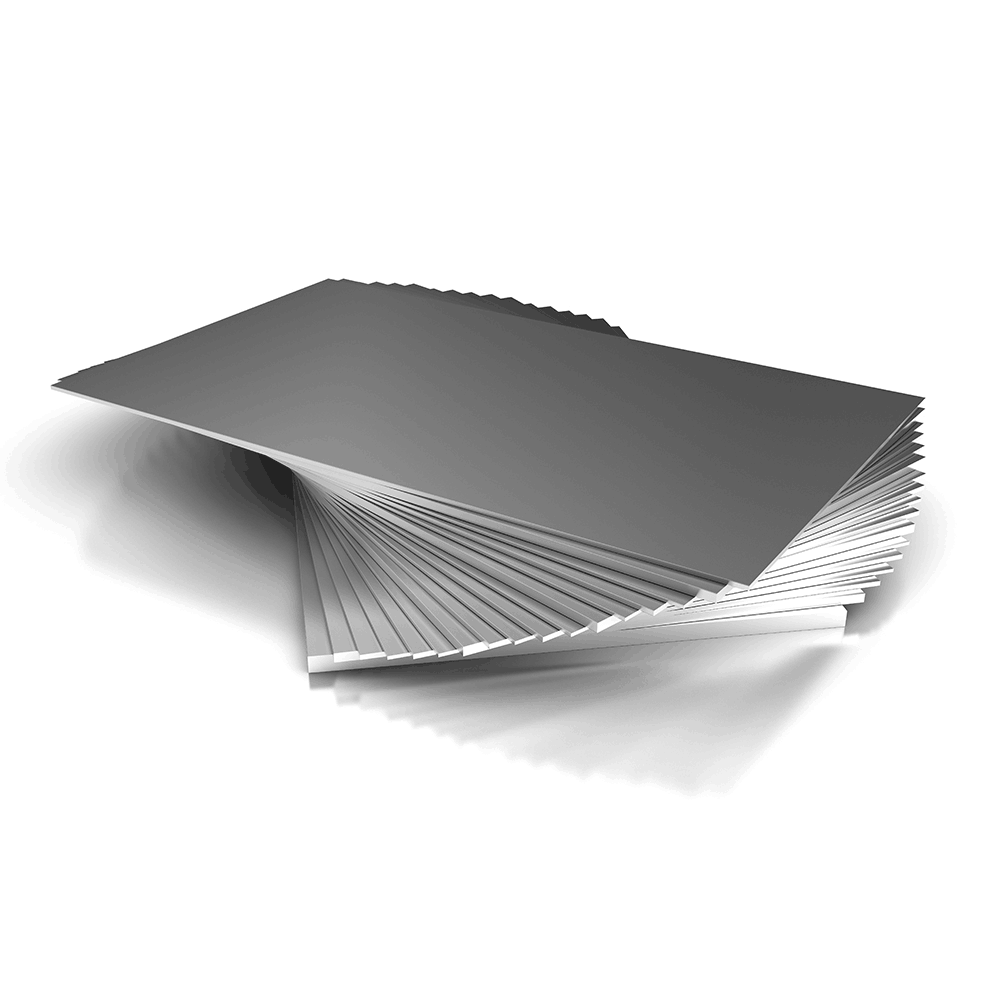

Strip | Cold Rolling | Tk0.20~2.50 | A | 1175~1470 | 5 |

B | 1470~1765 | 3 | |||

Wire | Cold Drawn | Dia0.20~5.00 | A | 1275~1570 | |

B | 1570~1865 | ||||

Physical Property of Elgiloy after aged | |

Item | Target |

Modulus of Elasticity E/Mpa | 196000~215500 |

Shear Modulus G/Mpa | 73500~83500 |

Density (g/cm3) | 8.4 |

Mean coefficient of linear expansion20-100°C/(10-6/K) | 14 |

Resistivity ρ /(μΩm) | 0.92 |

Magnetic Rate k/106 | 50~1000 |

Feature:

● very low thermal expansion coefficient between -250℃ and +200℃

● good plasticity and toughness

Application:

●Production, storage and transportation of liquefied gas

●Measuring and controlling instruments with operating temperature below +200℃, such as temperature regulating devices

● helical connector bushing between metal and other materials

● bimetal and temperature controlled bimetal

● membrane frame Low shadow mask

● CRP component tempering die for aerospace industry

● satellite and missile electronic control unit framework below -200℃

● auxiliary electron tube in the laser control device electromagnetic lens

Standard

AMS 5833

AMS 5834

AMS 5876

ASTM F1058

ISO 5832-7

ISO 15156-3

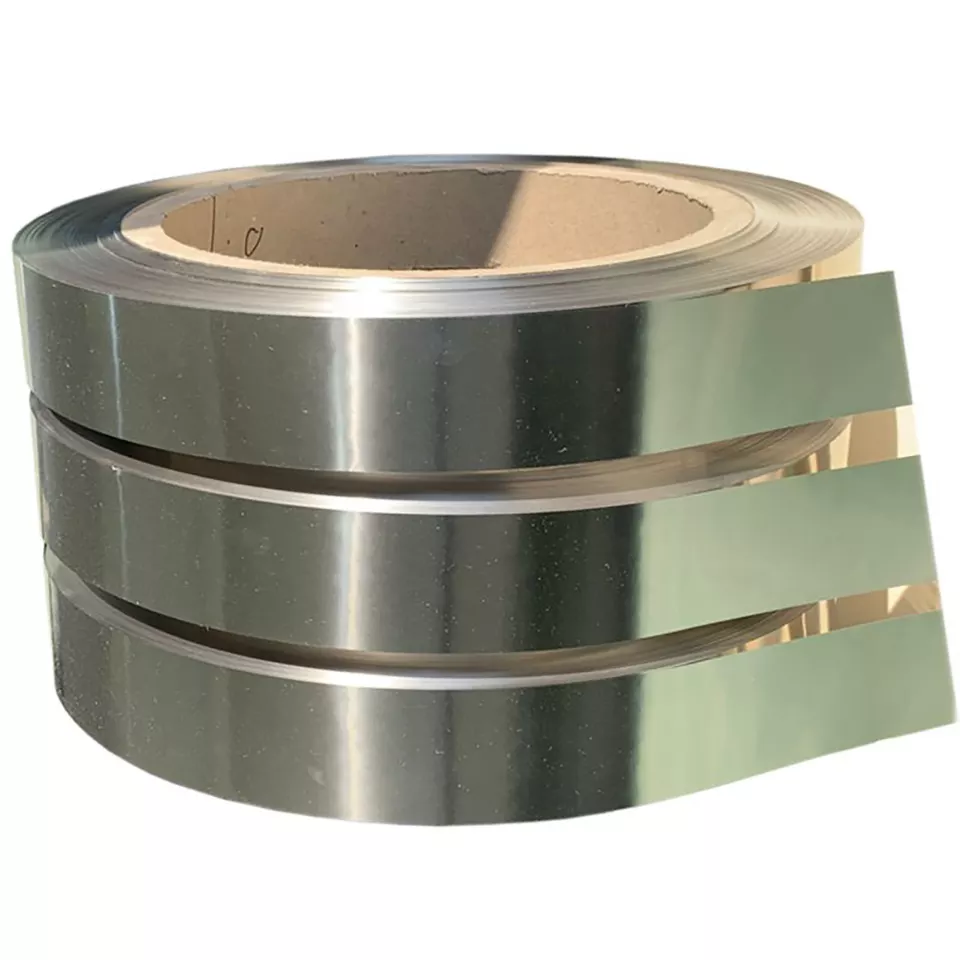

Forms available: Strip, wire