-

tel:

+86 17625110110 -

email:

klaus@hralloys.com

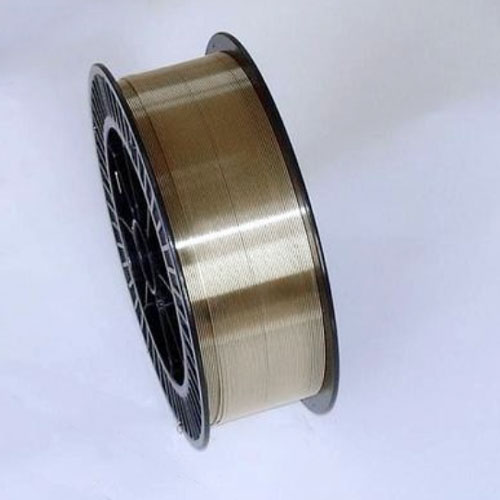

Hot-selling Welding Wire ERNiCrMo-3 with the Competitive Prices

Chemical Composition (%):

Ni | C | Mn | Fe | S | Cu | Si | Al |

≥64 | ≤0.1 | ≤0.5 | ≤1.0 | ≤0.015 | ≤0.50 | ≤0.50 | ≤0.40 |

Mechanical Properties of Deposited Metal

Test Item | Rm(N/mm2) | Rel/Rp0.2(N/mm2) | A(%) | KV2(J)-40 |

Reference Value | 785 | 555 | 42 | 90 |

Reference Current (DC+)

Size(MM) | CURRENT range (AMPS) | GAS flow rate(L/Min) |

Φ0.8 | 50~100 | 15 |

Φ1.0 | 50~220 | 15~20 |

Φ1.2 | 80~350 | 15~25 |

Φ1.6 | 170~550 | 20~25 |

Standard:

AWS A5.14, ERNiCrMo-3

ASME II, SFA-5.14, ERNiCrMo-3

ASME IX, F-No. 43

UNS N06625

Available Forms:

ERNiCrMo-3 is available on spool (Precision Layer Wound) and in cut straight lengths.

Straight Rods (TIG)-mm: 1.2-3.2

Spooled Wire (MIG)-mm: 0.8-1.2

Features:

1. An excellent resistance to oxidation under heating

2. A limitation of intergranular oxidation

3. High electrical resistance and long lifetime

4. Good performance of anti-carburizing, the atmosphere and surface of sulfur pollution

Packaging Details:

Wire is packed with waterproof paper or weave bag, into pallets or wooden case.Special packaging requirements can also be accommodated