-

tel:

+86 17625110110 -

email:

klaus@hralloys.com

ERNiCrMo-2 China Welding Wire Manufacturer for TIG and MIG

Specification:

Product Name | Nickel Alloy Welding Wire MIG/ TIG |

Standard | Nickel • AWS ERNiCrMo-2 AWS A5.14/A5.14M: ERNiCrMo-2 UNS N06002

|

Model Number | ERNiCrMo-2 ERNi-1 ERNiCrMo-3 ERNiCrMo-4 ERNiCr-3 ERNiCu-7 ERNiCrMo-14 ERNiCrMo-7 ERNiCrMo-10 ERNiCrMo-13 ERNiFeCr-1 ERNiCrFe-5 ERNiCrFe-7 ERNiCrCoMo-1 etc. |

Package | MIG Spool : S100/1kg(2lb) S200/5kg S300/15kg or customized TIG: 2kg/boxes 5KG/boxes 10kg/boxes or customized SAW Coil: 25kg/coil 50kg/coil or customized |

Size | TIG-rods(mm): 1.6;2.0;2.4;3.2;4.0;5.0 or customized MIG-wires(mm): 0.8;0.9;1.0;1.2;1.6;2.0;2.4 or customized SAW WIRE(mm): 1.6; 2.0 ; 2.4 ; 3.2 ; 4.0 ; 5.0 or customized |

Certification | CE ISO ABS etc. |

Application | welding all kind Nickel Alloy structure or different metals |

OEM | accept |

MOQ | 15KG |

Price Term | FOB , CNF, CIF , EXW |

Payment | T/T, L/C, West Union,Credit Card |

Inspection | SGS,BV or as required |

Loading Port | Any port of china |

KEY FEATURES:

The Ni-Cr-Mo alloy system provides excellent resistance to oxidizing and reducing environments.

Meets AMS 5798G chemical and tolerance requirements.

Typical Applications:

Used for TIG and MIG welding of nickel-chromium-molybdenum alloys.

Chemical Composition (%):

Cr: 20.5-23.5, C: 0.05-0.15, Mn≤1.0, Fe: 17.0-20.0, S≤0.01, Co: 0.5-2.5, Si≤1.0, Al≤0.1, Mo: 8.0-10.0, W:0.2-1.0, B≤0.05, P≤0.015, Ni: Bal.

Available Forms:

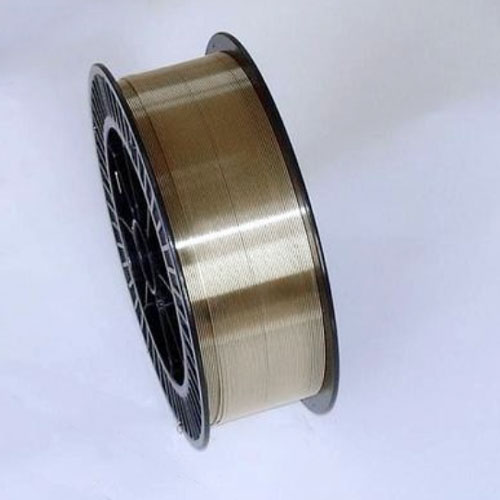

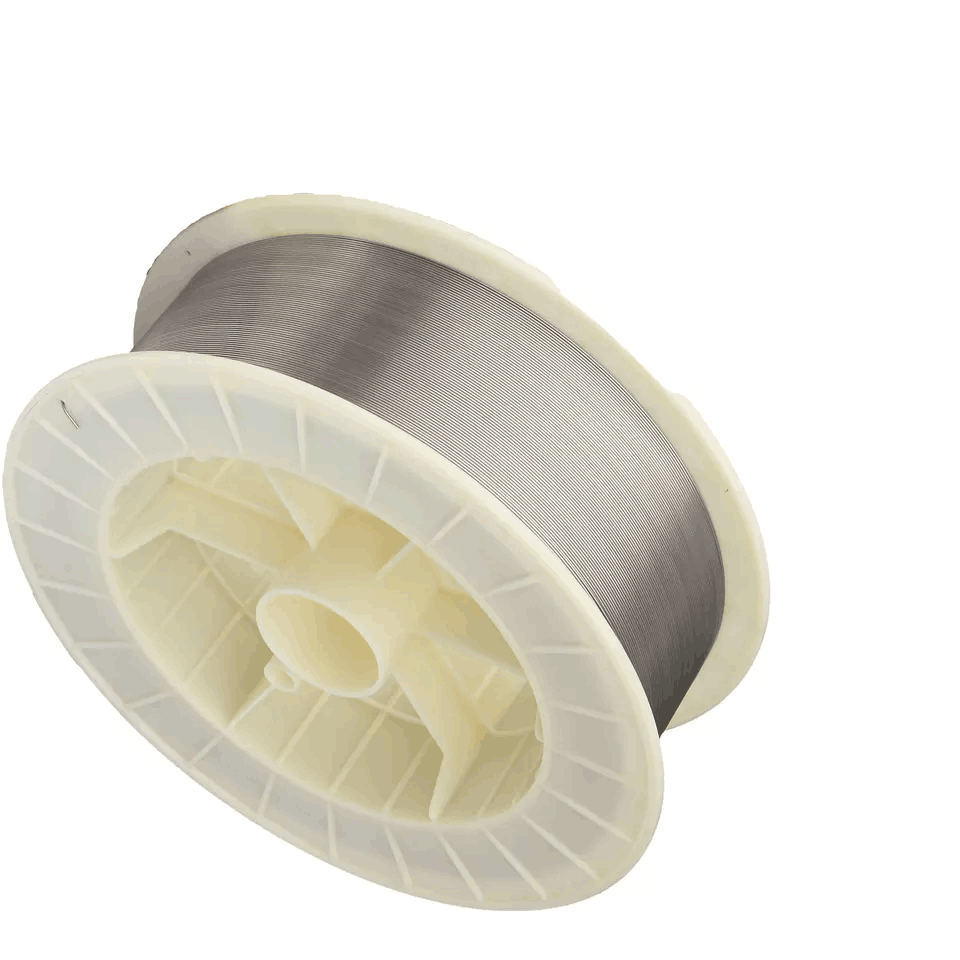

ERNiCrMo-2 is available on spool (Precision Layer Wound) and in cut straight lengths.

Straight Rods (TIG) and Spooled Wire (MIG).

Packing and shipping

MIG(15kgs/spool), TIG(5kgs/box),Strip