-

tel:

+86 17625110110 -

email:

klaus@hralloys.com

ASTM A638 Nickel-based Round Bar Incoloy A-286 / UNS S66286 / 1.4980

Description

Limiting Chemical Composition (%):

Element | Min % | Max % |

C | 0.03 | 0.08 |

Mn | 1.00 | 2.00 |

Si | – | 0.50 |

P | – | 0.02 |

S | – | 0.015 |

Cr | 13.50 | 16.00 |

Ni | 24.00 | 27.00 |

Mo | 1.00 | 1.50 |

Ti | 1.90 | 2.30 |

B | 0.003 | 0.01 |

V | 0.10 | 0.50 |

Co | – | 1.00 |

Al | – | 0.35 |

Cu | – | 0.50 |

Pb | – | 0.005 |

Fe | Bal |

Alloy-A286 include Features:

1,Excellent fabrication characteristics

2,High mechanical properties due to age-hardenability

3,High ductility in notched sections

4,Good creep-rupture strength during extended high-temperature exposure

5,Can be produced by AOD reefing or vacuum induction melting

6,Good for moderate corrosion applications in aqueous solutions

Applications:

Fasteners and Exhaust Parts, Gas Turbines, Jet Engines, Super Charger Components, Wheels.

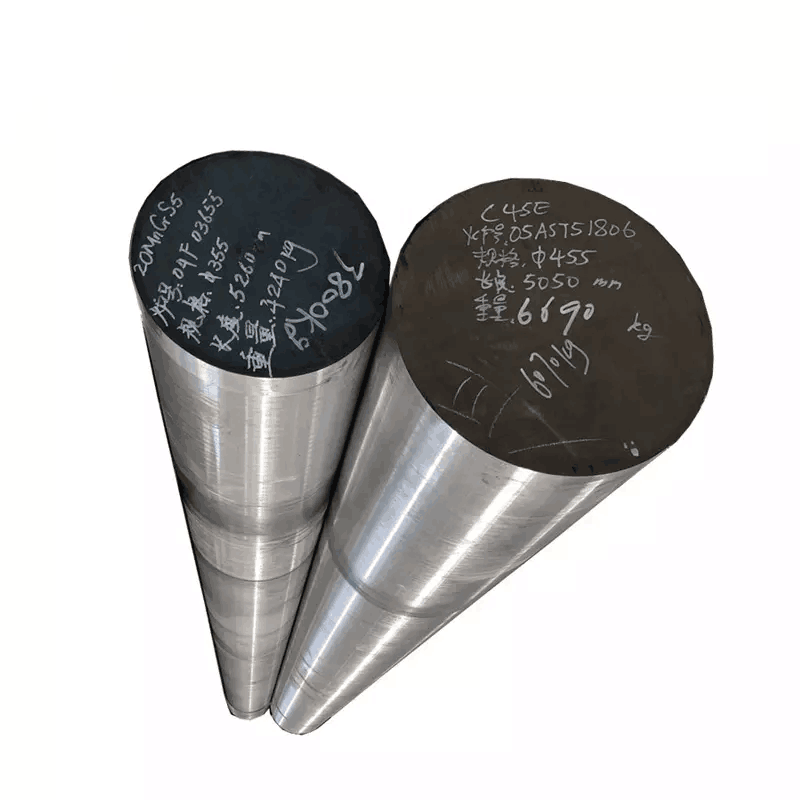

Forms Available:

Round and Flat Bar, Cold Heading / Upsetting Coil.