-

tel:

+86 17625110110 -

email:

klaus@hralloys.com

Chemical Composition (%)

Alloy | Ni % | Mn % | Fe % | Si % | Cu % | C % | S % |

Nickel 201 | Min 99 | Max 0.35 | Max 0.4 | Max 0.35 | Max 0.25 | Max 0.02 | Max 0.01 |

Nickel 200 | Min 99.2 | Max 0.35 | Max 0.4 | Max 0.35 | Max 0.25 | Max 0.15 | Max 0.01 |

N6 | Min 99.5 | Max 0.05 | Max 0.1 | Max 0.1 | Max 0.1 | Max 0.1 | Max 0.005 |

N4 | Min99.9 | Max 0.002 | Max0.04 | Max0.001 | Max0.015 | Max0.01 | Max 0.001 |

Product Features:

Stable performance; Anti-oxidation; Corrosion resistance; High temperature stability; Excellent coil-forming ability; Uniform and beautiful surface condition without spots.

Mechnical Properties

FORM | Yield Strength (Mpa) | Tensile Strength (Mpa) | Elongation (%) | Hardness (RB) | |

Bar | Hot-finished | 105-310 | 60-85 | 55-35 | 45-80 |

Cold-drawn,annealed | 105-210 | 55-75 | 55-40 | 75-98 | |

Strip | Hard | 480-795 | 620-895 | 15-2 | >90 |

Annealed | 105-210 | 380-580 | 55-40 | <70 | |

Wire | Annealed | 105-345 | 380-580 | 50-30 | |

No.1 Temper | 275-520 | 485-655 | 40-20 | ||

Spring Temper | 725-930 | 860-1000 | 15-2 | ||

Standards:

ASTM B-162

ASME SB-162

Applications: High-purity nickel foil is used to produce battery mesh, heating elements, gaskets, etc.

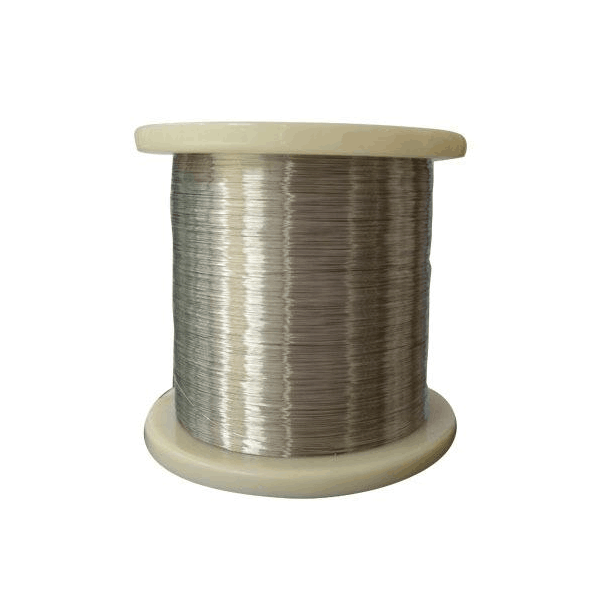

Available Product Forms: Pipe, tube, sheet, strip, plate, round bar, flat bar, forging stock, hexagon and wire.

Packing:

Nickel wire is rolled on ABS spool or as coil with waterproof paper or weave bag, into carton boxes, pallets or wooden case.Special packaging requirements can also be accommodated.

OEM is also acceptable.